Demand Planning for S&OP TBD Live Web Workshop Certified Analyst in Demand Planning (CADP) TBD *Available as a Virtual Zoom Workshop Below are brief descriptions of current DemandPlanningNet customized workshops, available through the web or onsite at your location Please visit our eThe Sales and Operations Planning Process (S&OP) is best defined as a planning process to ensure the business maintains sufficient inventory to meet customer demand The S&OP process typically operates on a monthly cadence, and includes a series of meetings that drive alignment between sales, marketing, and supply chain Manufacturing, distribution and supply chain management are all about recognizing and satisfying demand This imperative comes together in a process known as sales and operations planning (S&OP), where the executive management team creates and maintains a plan that states how the company will use its resources people, equipment, cash, inventory, warehouses, etc to satisfy demand

A Paradigm Lost It S Not All About Changes In Demand

S&op demand planning

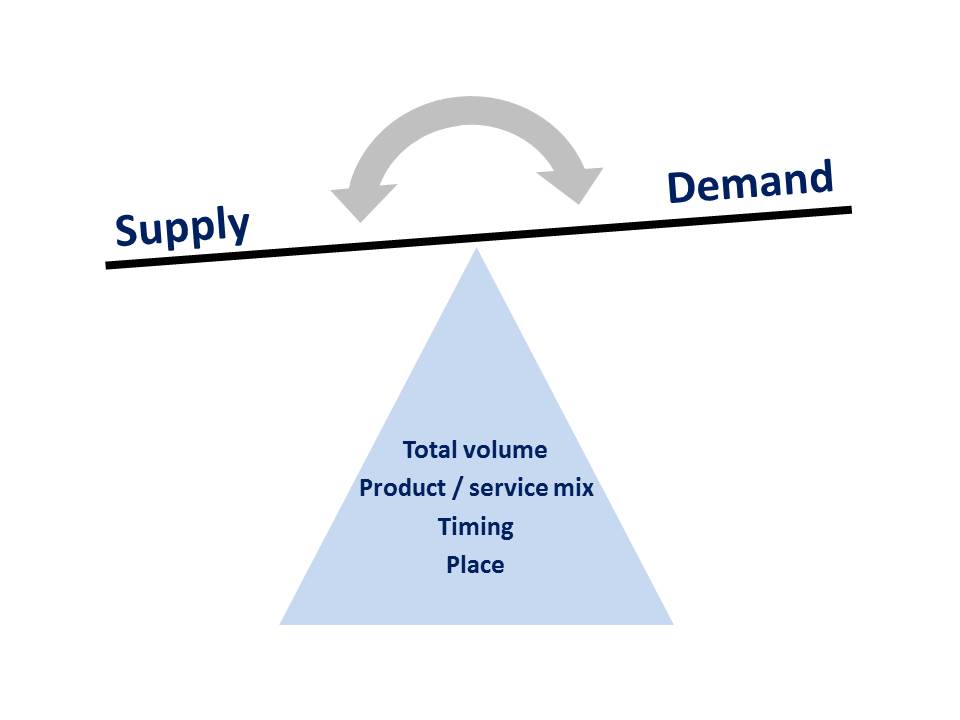

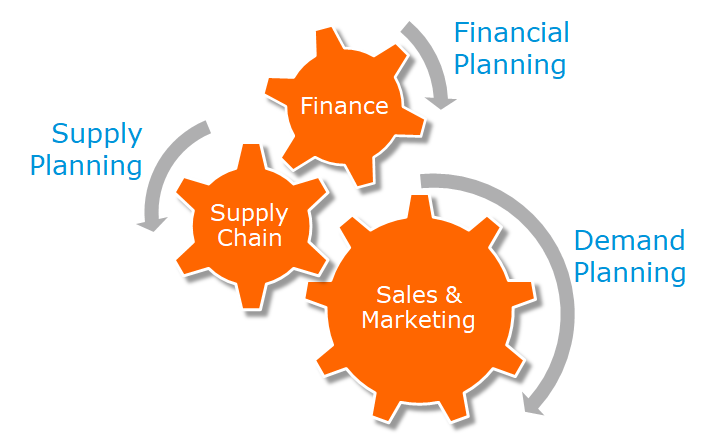

S&op demand planning-Diagnostic and Design We help companies roll out best practices in demand management and S&OP Study your planning process in the context of your business model and bestinclass practices and develop business processes and implementation More Demand planning is the process of balancing supply and demand to maximize business efficiency and profit Sales & Operations Planning (S&OP) is the cross functional, collaborative process required for effective demand planning, which makes use of sales forecasts to make optimal planning decisions

1

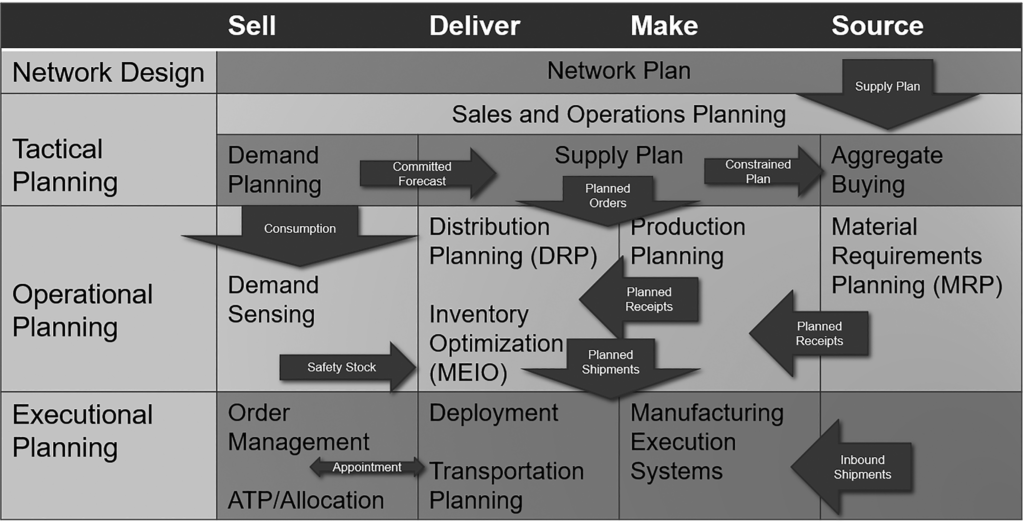

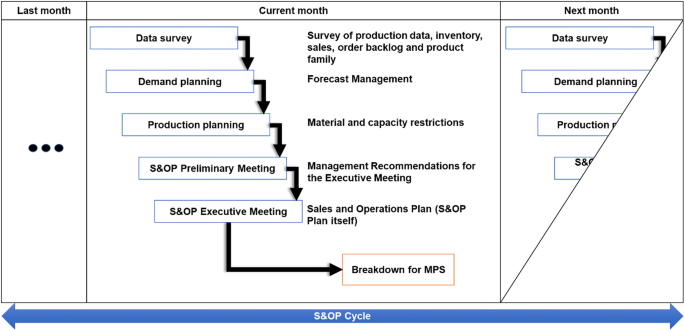

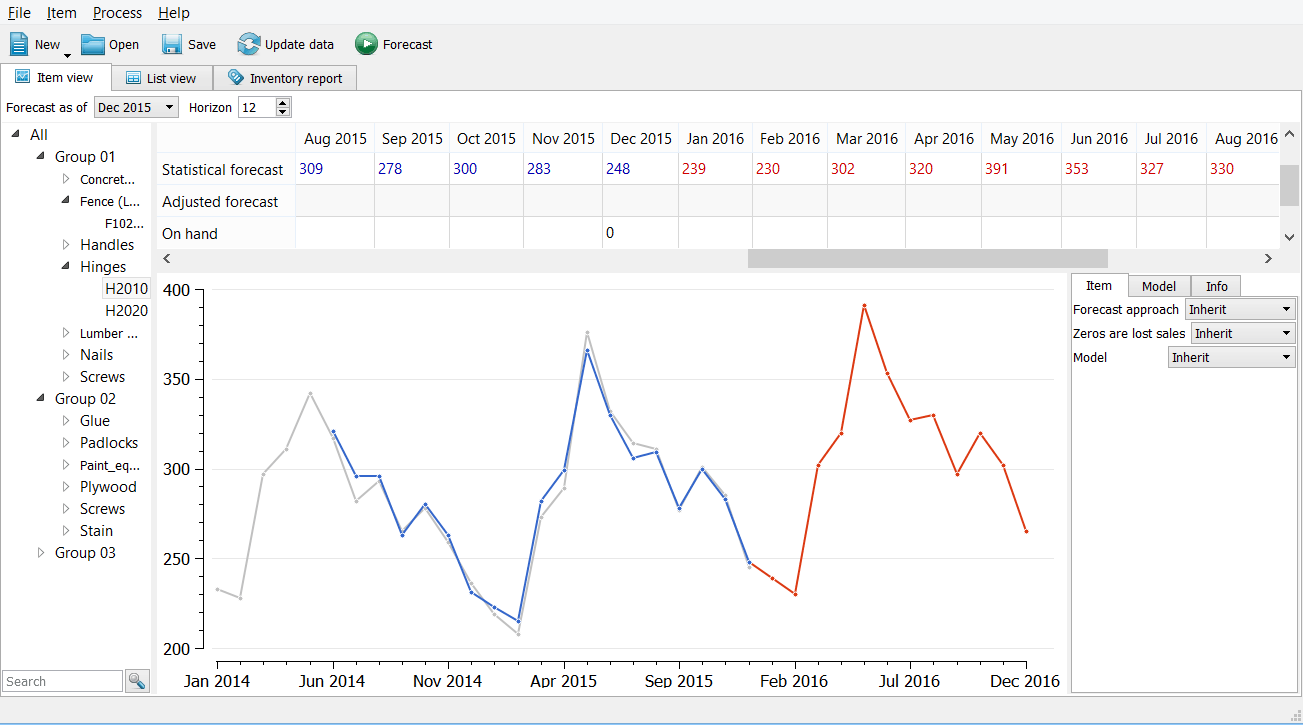

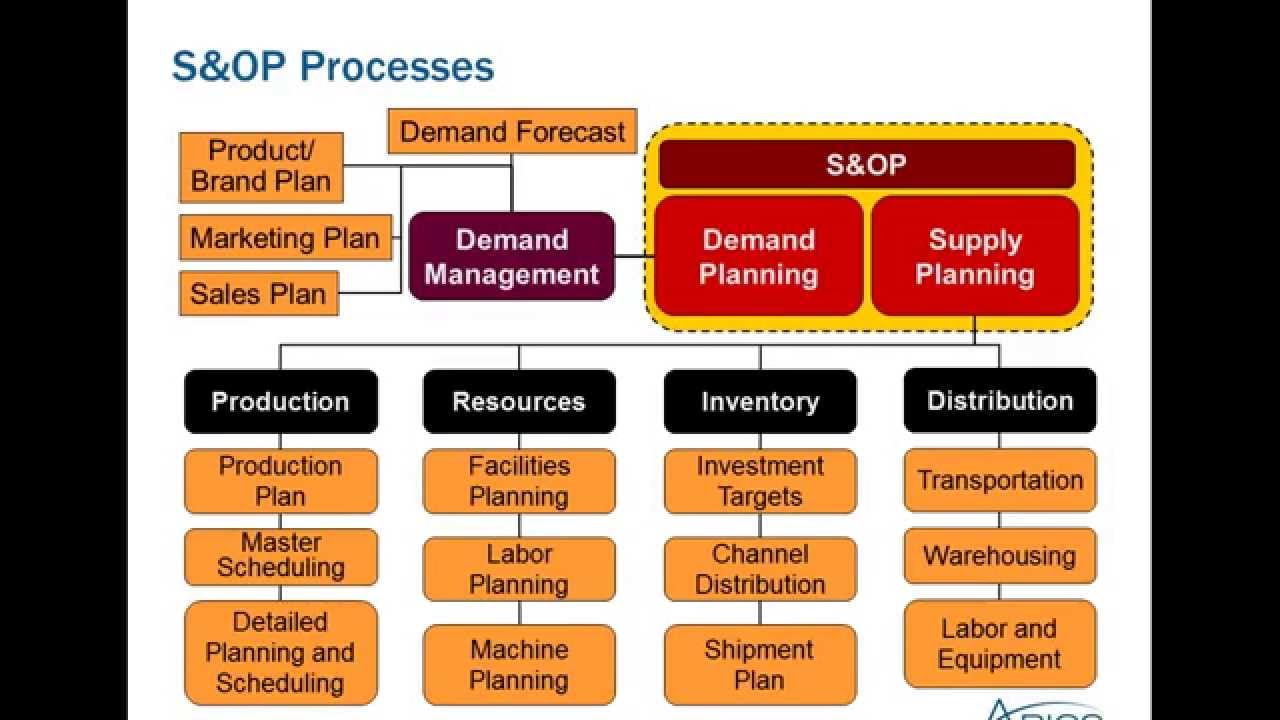

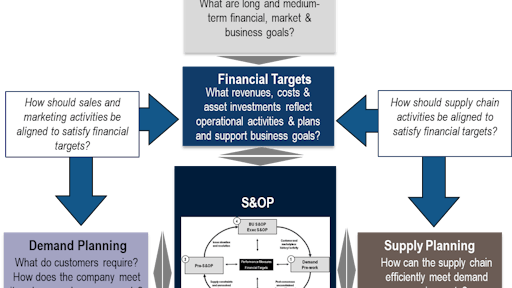

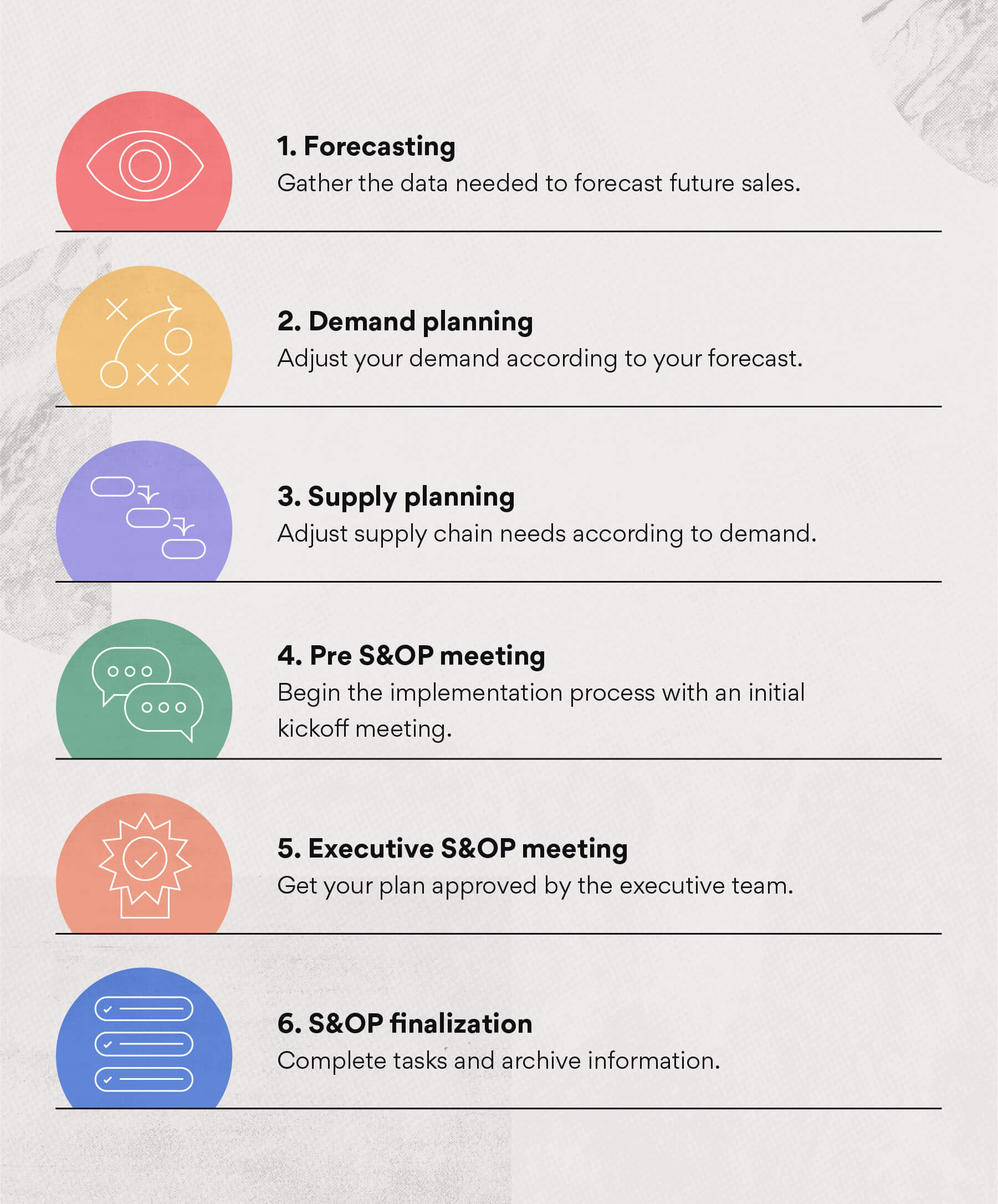

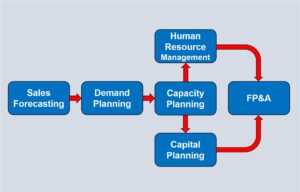

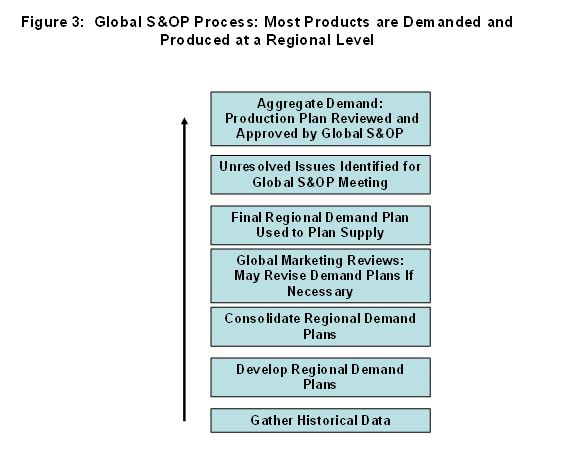

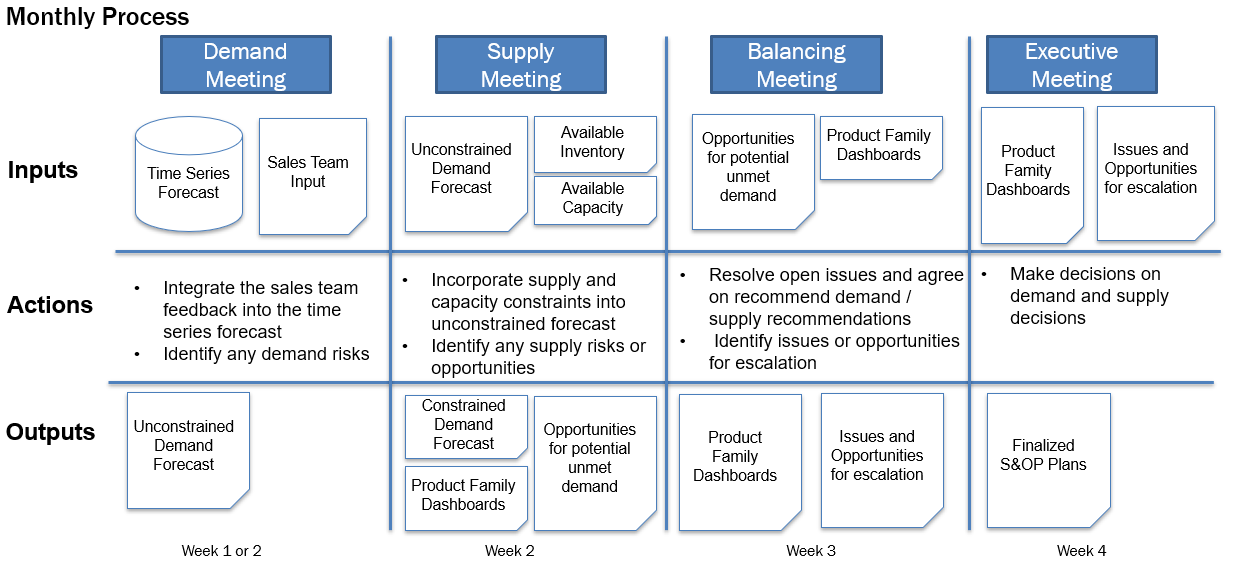

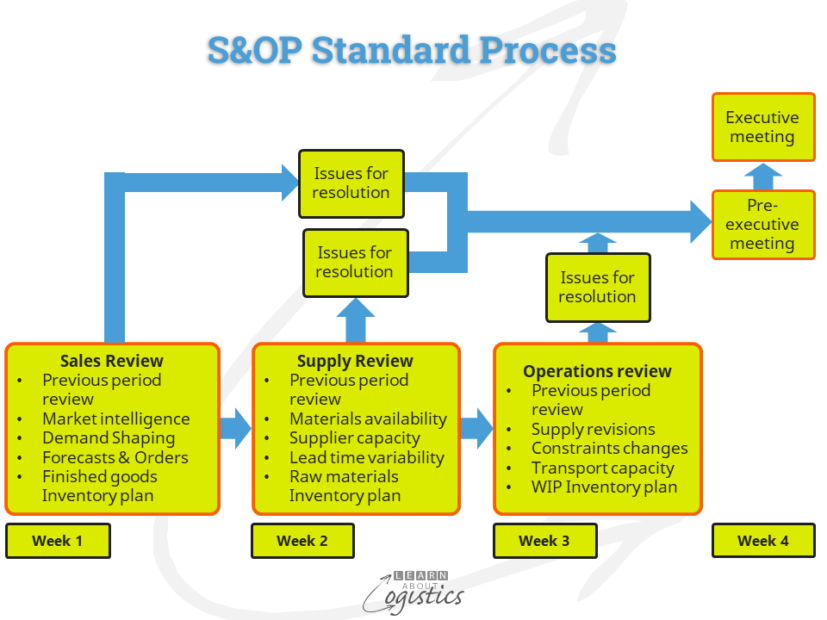

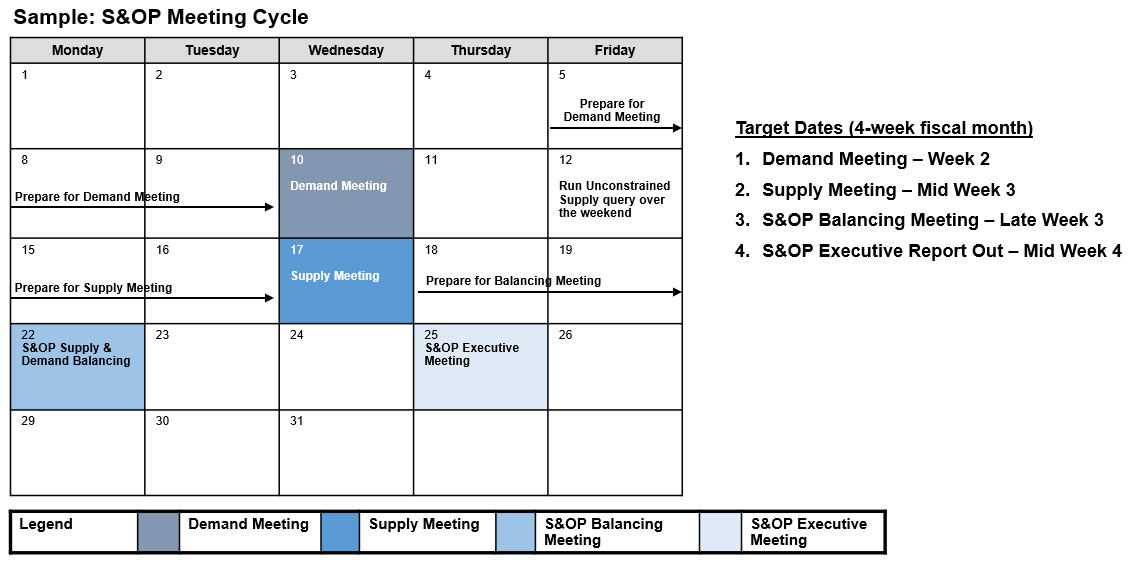

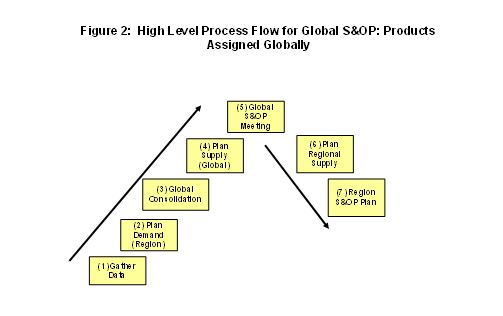

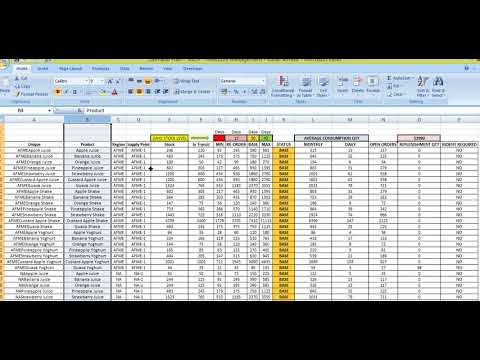

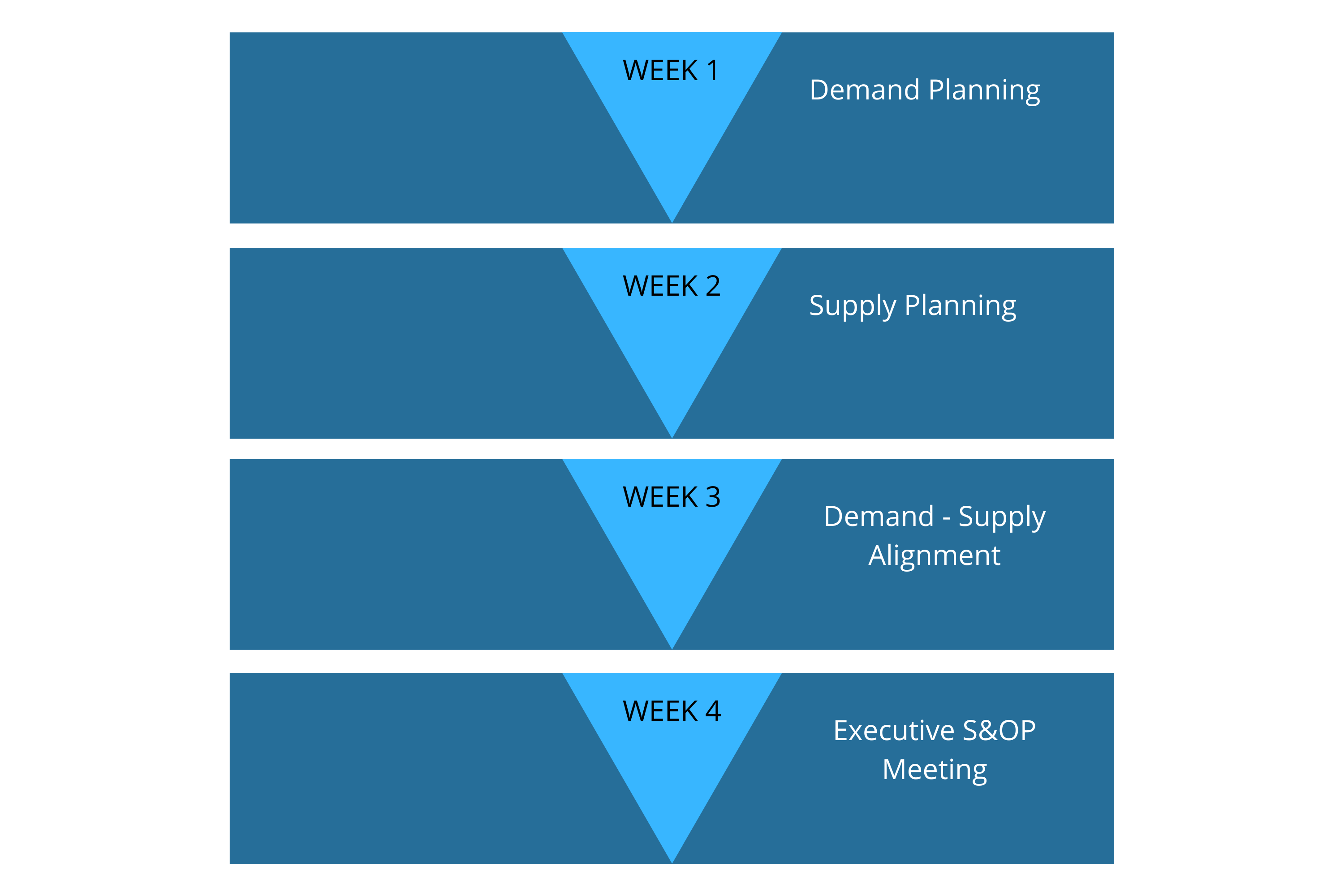

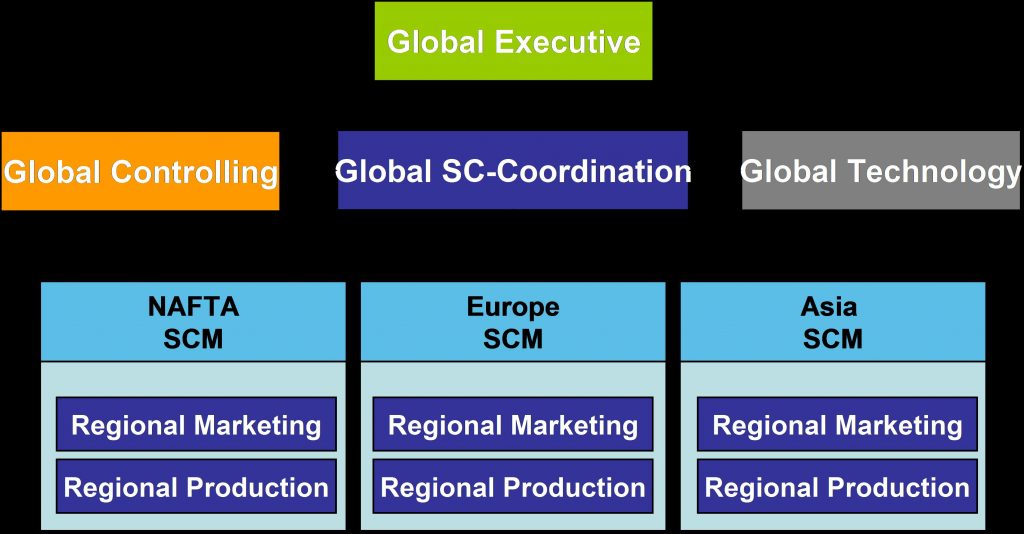

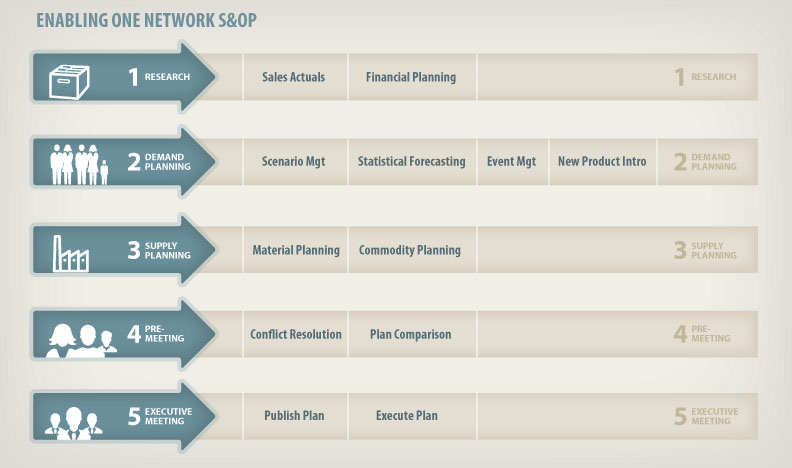

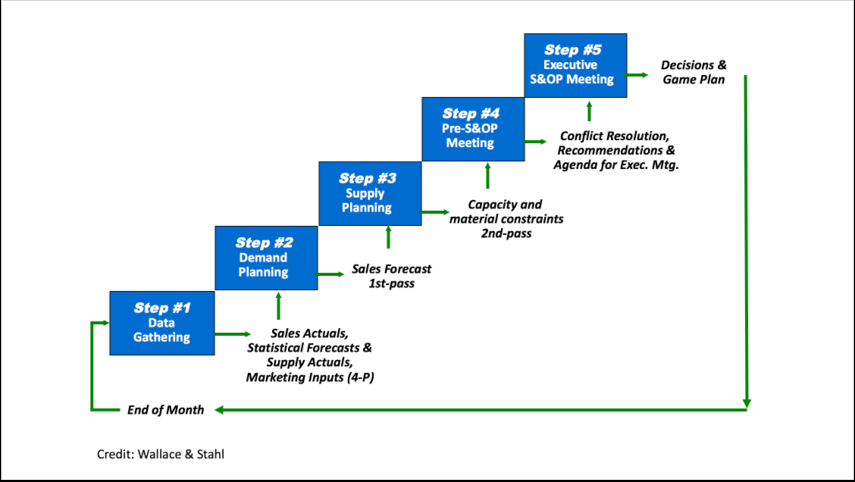

The sales and operations planning process delivers an updated, rolling operational plan and demand plan that typically extends 18 months to 36 months into the future By optimizing resources to best meet demand while maximizing revenue and profit, S&OP delivers more effective and resilient supply chain management, which is always crucial but even more so during Recognize going into the process that a number of market and organizational factors will influence the success of your sales and operations plan The biggest challenge is being able to identify patterns and draw connections between internal and external factors that may influence supply/demand and your S&OP process Demand Planning finalizes the demand plan, and hands it over to Supply Planning on day seven Supply Planning creates a replenishment plan by the ninth workday A preS&OP meeting by global region occurs on the tenth workday

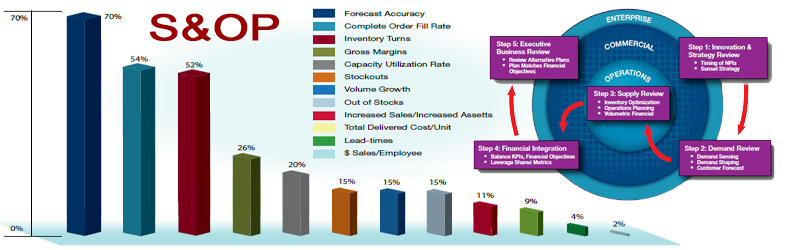

Demand Planning for S&OP Workshop is a specialized twoday course, where we will explain the modeling methodology and process behind accurate demand forecasts and how to effectively use promotional information to arrive at a consensus forecastProvide demand planning input and forecast to business analyst (for each segment) for review Ensure data generated by Sales business analysts is suitable for S&OP process Initiate improvement actions when required Write S&OP meeting minutes, communicates key conclusions to stakeholders (sales & finance) and performs followup of actions Demand Planning is just one of five steps of the whole S&OP process The Demand Planning step uses the statistic sales forecast and the experience of other areas in order to estimate future demand

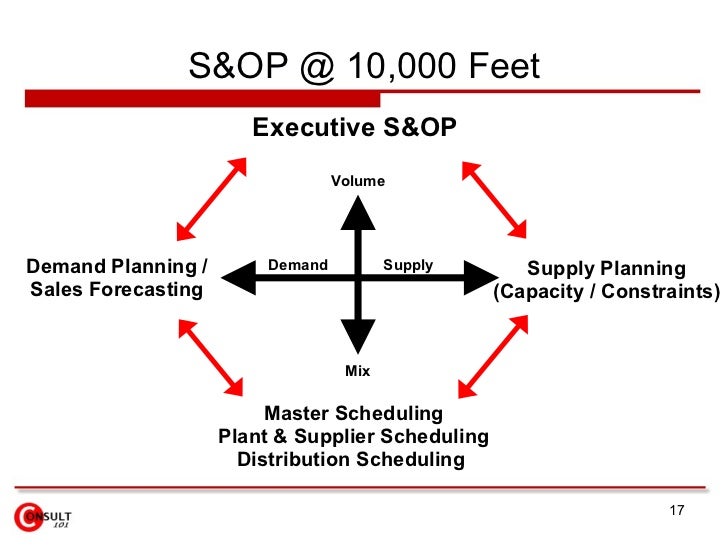

One of the most important is the demand plan, which contains projected sales forecasts and other demandrelated data In order for the demand plan to capture the information that all consumers of the S&OP will need, those responsible for creating the demand plan would do well to address several key questionsS&OP Meetings An S&OP Process Is Driven by a Baseline Demand Forecast • Unconstrained Demand Forecast • Constrained Demand Forecast • Supply Plans •Rough Cut Supply Plans •Supply Constraints Demand Supply •Baseline Demand Forecast • Must be estimate of true unconstrained demand • The "Sanity" check • Must represent unbiased, unemotional viewAn Executive Whitepaper Successful Sales and Operations Planning in 5 Steps LOGILITY VOYAGER SOLUTIONS wwwlogilitycom 2 Executive Overview The Sales and Operations Planning (S&OP)1 process is well known and understood in the world of supply chain management

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Achieve Excellence In Sales And Operations Planning Sapinsider

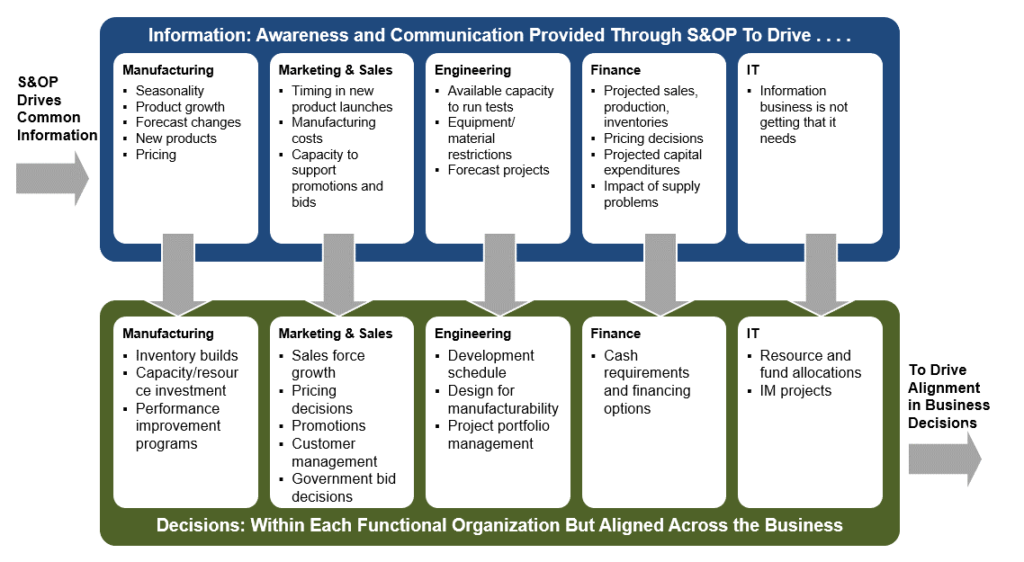

The final goal is to collect some useful information for the S&OP process in order to make sure that we are planning demand properly Among any supply chain planning applications, we can say that demand planning is the most miscomprehend as well as frustrating one Demand planning /ERP systems must build a connected supply chain Cristian Circiumaru Cristian is a supply chain professional involved in designing and embedding top tier S&OP processes, including selection and deployment of supporting technology With over 10 years experience in demand planning , business operations and manufacturing , he spent time in global S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making It integrates demand, supply, operations, and financial planning into one game plan for business

S Op Implementation Roadmap

Demand Planning Net Inventory Management And Optimization In Boston Ma

As a highlevel executive strategy system, S&OP starts with gathering data about variables such as sales forecasts, cash on hand, and inventory From there, a formal meeting for demand planning ensues to build forecasts without inputS&OP & Demand Planning Executive North Asia Job Summary JOB SCOPE This position reports directly to the S&OP & Demand Planning Manager, He/she will manage the country's S&OP process for sales (given scope below) with aim to align the S&OP process with Imerys S&OP BluePrint Given Scope PMAPAC North Asia (China, Japan, Taiwan and Korea)About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

S Op Effectiveness Recommendations To Make The Leap Supply Chain Shaman

What Is One Plan S Op Arkieva

Sales & Operations Planning (S&OP) – Demand Planning Sales and Operations Planning (S&OP) is a powerful decision making tool for business executives as well as line managers According to Tom Wallace, "S&OP enables the company's managers to view the business holistically and gives them a window into the future" S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change In practice, it is called a replanning process S&OP is owned by the GM or CEO It is a crossfunctional process and includes all the functions of the company Correctly implemented, it is a demand and strategydriven processEric is a predictive analytics and business planning innovator, author, and speaker He is the Director of Thought Leadership at the IBF Prior to this he worked as the Director of Demand Planning at Escalade Sports, Director of Demand Planning at Berry Plastics, and Director of Demand Planning & S&OP at Tempur Sealy International

Sales Operations Planning Why Is S Op Important

Monthly S Op Process Sales And Operations Planning Wikipedia Sales And Operations Planning Best Apps For Teachers Apps For Teachers

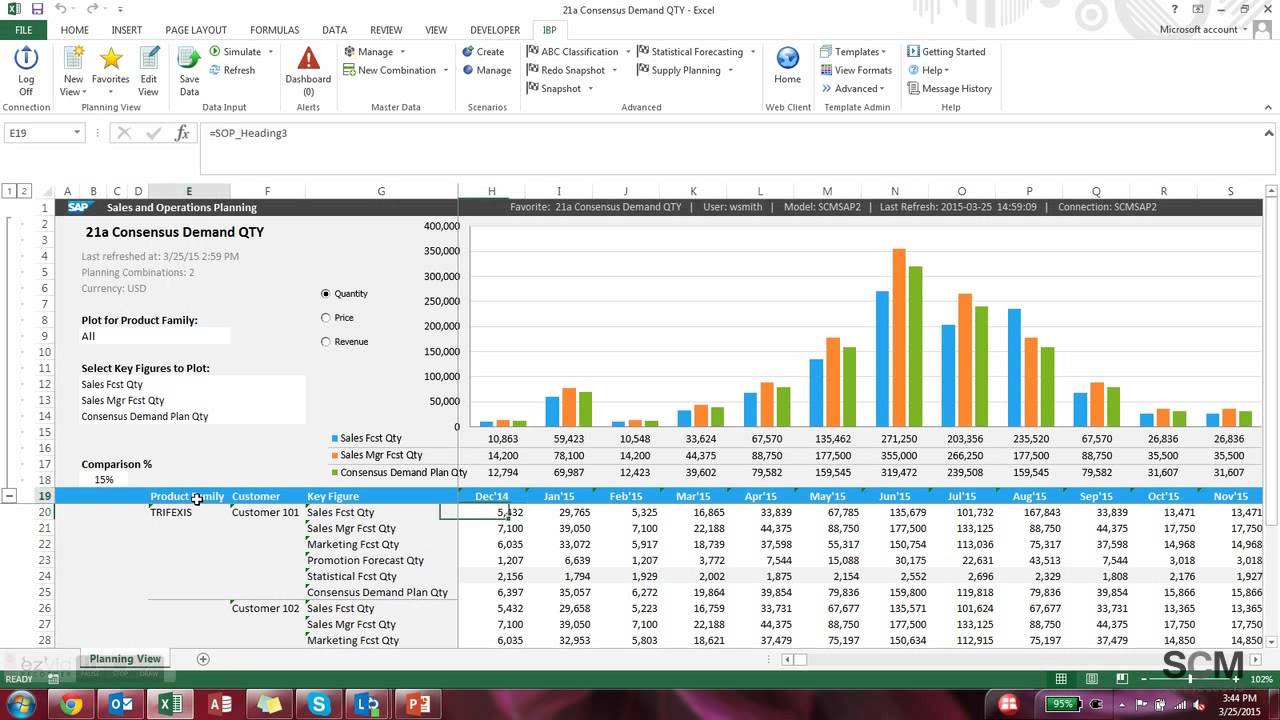

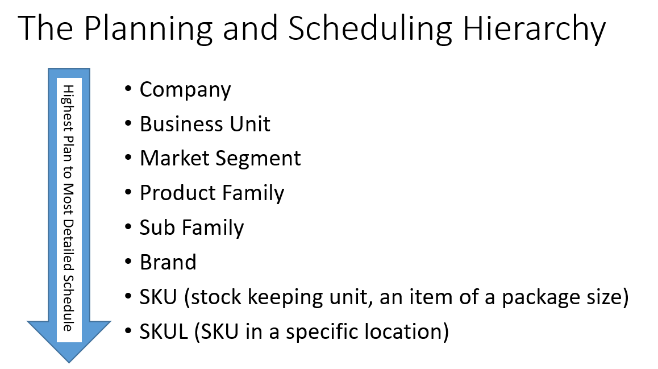

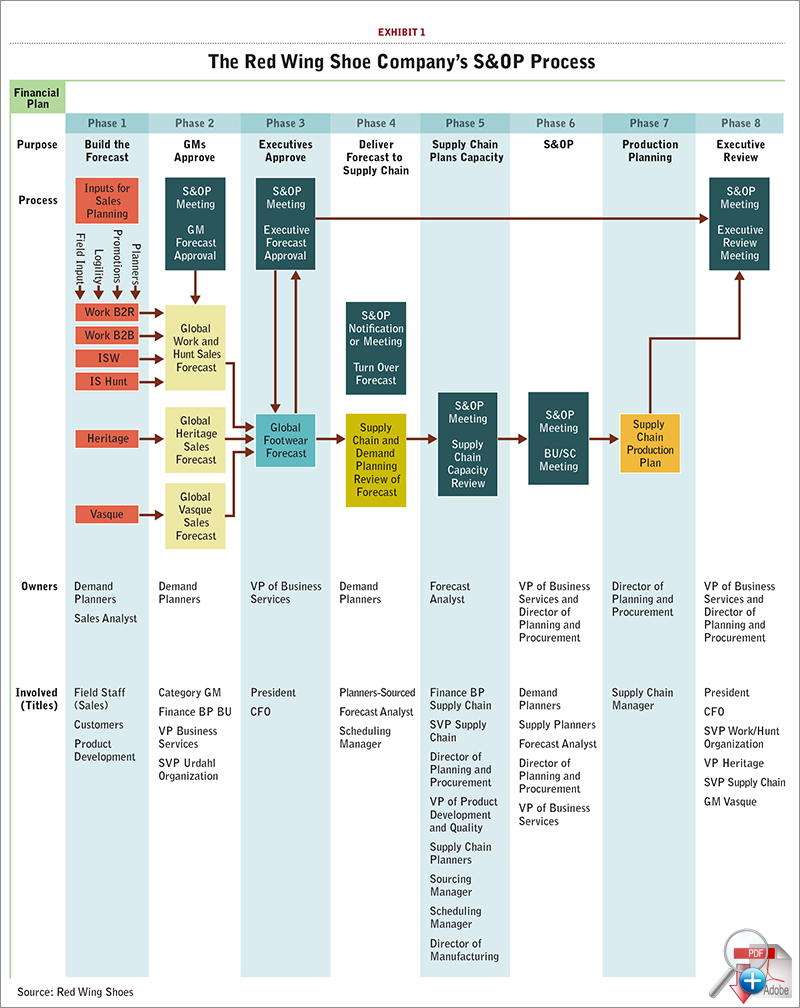

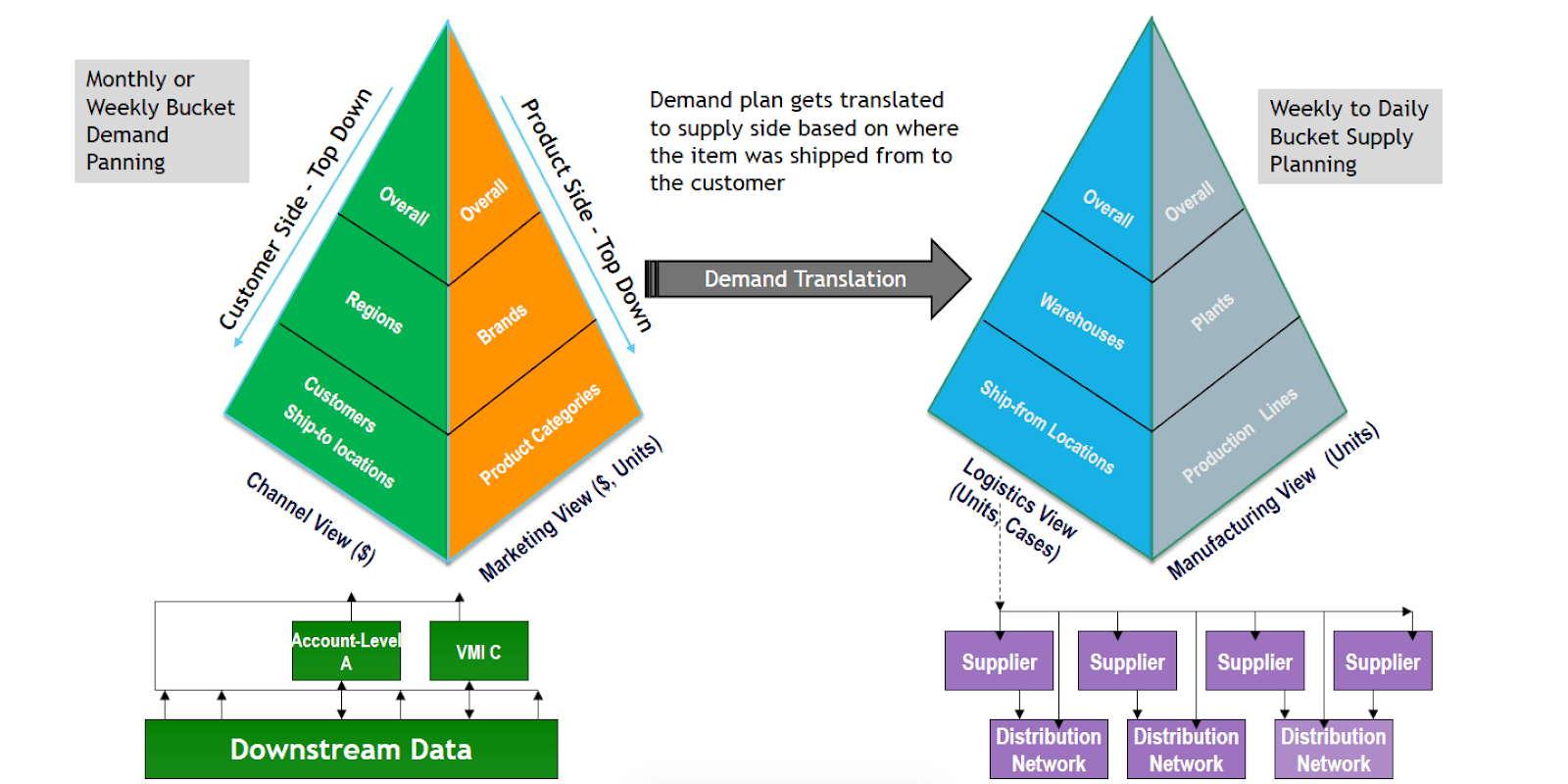

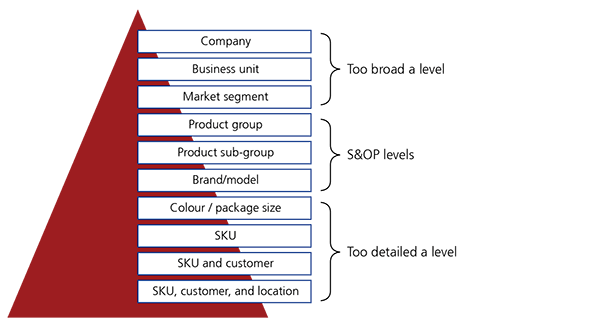

Sales and Operations Planning (S&OP) Manufacturers in the Consumer Packages Goods Sector were the early adopters of Supply Chain Forecasting Catering to the firm demands of the Retail Partners, CPG manufacturers focused on minimizing the forecast error to drive fill rates and lower inventory carrying costs As a natural progression, CPG companies started adopting S&OP Powered by SAP HANA inmemory technology, this cloudbased solution combines sales and operations planning (S&OP), forecasting and demand, response and supply, demanddriven replenishment, and inventory planning Each month or planning period, the S&OP demand and supply planning process follows a very specific linear work flow as outlined in this article Setting a planning hierarchy is a critical part of generating appropriate forecasts The demand planning hierarchy is top down one to many within the sales level and also within the product level

Sales And Operations Planning Defined

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

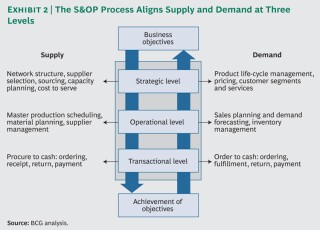

Demand planning includes validating forecasts, understanding sources of demand, accounting for variability, and revising customer service policies Additionally, it encompasses the inclusion of promotion plans, onetime events, and new product and customer launches The sales and operations planning process enable the company to effectively manage the demand of its customers It holds the capacity of its operations too Sales and operations planning generates a uniform and agreedto set of numbers used to drive the business It specifically integrates strategic, tactical, and operational planningIt can be stressful working with generalist search firms that don't understand the difference between demand planning and supply planning, or S&OP and IBP You need a supply chain recruiting partner that's experienced across all aspects of inventory planning, spanning demand forecasting through supply, and leverages a qualityassured

Supply Demand Optimization Aps S Op Anaplan Community

A Comprehensive Overview Of Sales And Operations Planning S Op

Valtitude / Demand Planning LLC specializes in helping businesses improve their planning across their Value Chain We provides consulting services and solutions implementation in Demand Planning, Integrated Business Planning (IBP), S&OP, and Supply Chain Optimization Value Chain Planning involves a larger focus on planning across the entire When operating at the top of their game, the forecaster needs to be able to challenge their commercial counterparts (who are often at more senior grade levels in the business) This applies most often to the process of agreeing a consensus forecast in the demand review stage of S&OP The paper goes on to make the following points 1 When IBP is running correctly, a company's leadership and management team continually replans on a rolling 24month horizon 2 The IBP process should be driven by demand in the marketplace —

How The Right Executive S Op It Tools Help You Flex For Growth Chainalytics

S Op Process

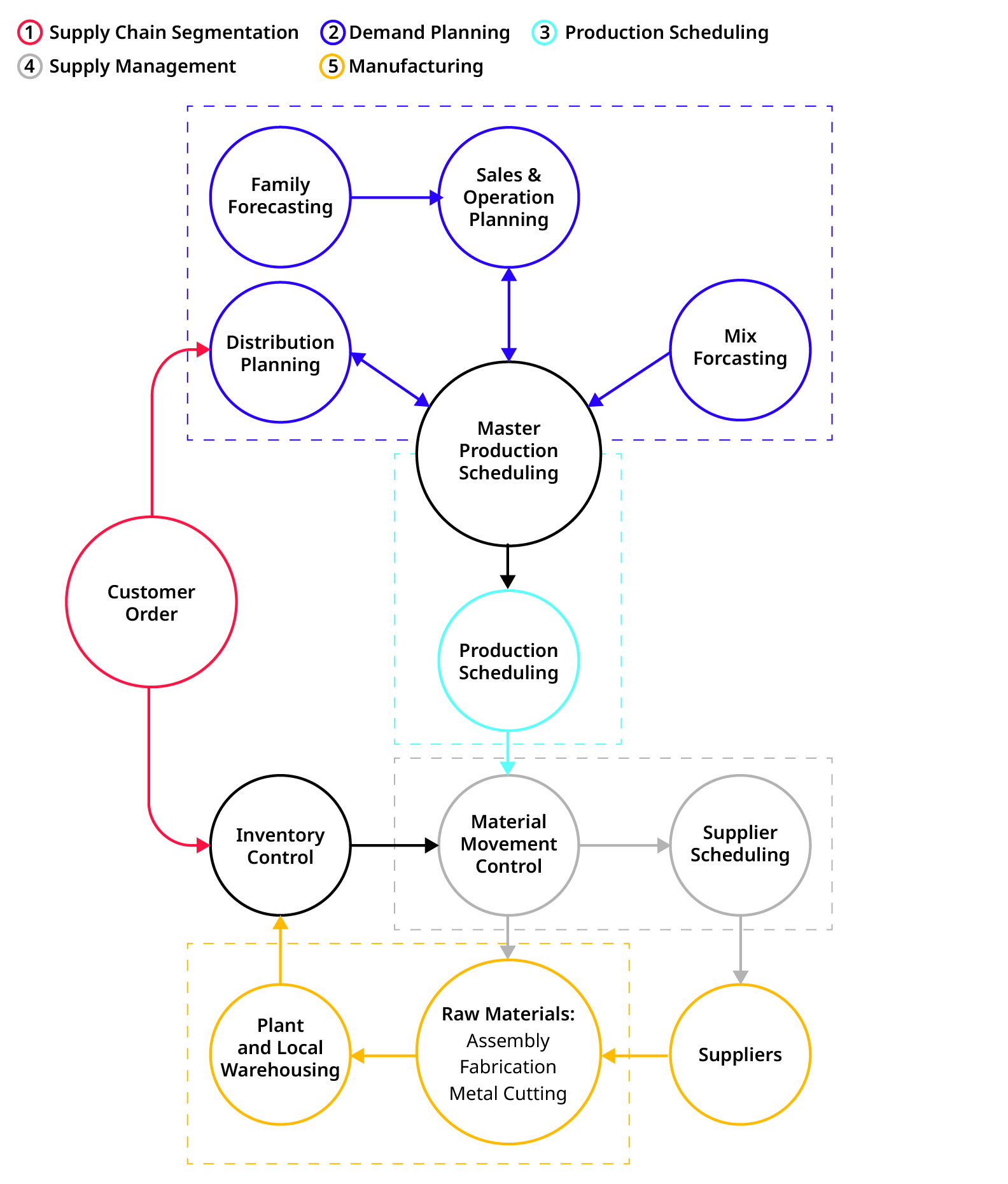

The demand planner's role in the S&OP process typically places him/her in the Operations Department Therefore, they frequently serve as a link between a company's Sales and Marketing Organization and their Manufacturing OrganizationSales & Operations Planning Demand Sensing reduces demand variability by extracting signals out of noisy demand, provides earlier demand insights, and enables more accurate shortterm plans and faster reactions to market changes ToolsGroup's Sales & Operations Planning (S&OP) solution helps companies achieve both higher levels of S&OPDemand Planning is an Integral Part of S&OP S&OP is a collaborative process to arrive at a balanced demand and supply plan Using collaboration to arrive at Demand Planning provides a better signal to the S&OP/IBP process S&OP Strategic Plan Master Schedule Demand Plan Production and Material Plan Three to five year strategic plan for the family

Advanced Planning System As Support For Sales And Operation Planning Study In A Brazilian Automaker Springerlink

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

S&OP processes which are driven by a layer based approach look at demand planning as the first step of a demand planning implementation The focus of this approach is towards enabling the ability to generate demand forecasts at a SKU/Location combination or maybe at a higher level of the product hierarchy for a period of say 812 months Demand management will always be a challenging element of the S&OP process Complaining about forecast inaccuracy is a waste of time because there will always be demand uncertainty Eliminating as much bias out of your planning process, however, is both within your control and an essential tactic for protecting your marginsCity Demand Planning, and S&OP Lead Direct Reports 2 Accountable for the Demand Planning and the S&OP process at the Canadian affiliate to ensure alignment of sales plans within the supply chain Managed indirectly team of 16 and $500,000 annual budget

What Is S Op How S Op Works Demand Planning Com

Demand Planning Software Solution Demo One Plan S Op Arkieva

Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment and synchronization among all functions of the organizationThe S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new product The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as a starting point, not much else can happen in the cycle There would be no supply and demand balancing exercise, plan valuation, or scenario Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted sales

Sales And Operations Planning Explorescm

10 Best S Op Software 21 Download Free Right Now Gmdh

Sales And Operations Planning Report Do You Get Surprises

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Sales And Operations Planning S Op Logistiikan Maailma

Getting To Grips With Sales And Operational Planning Bloor Research

Apics Monadnock Chapter Webinar Fundamentals Of S Op Youtube

1

What Is Sales Operations Planning Supply Chain Minded

S Op Planning Workshop

Improving Profitability With Sales Operations Planning Magellan Consulting Group

2

The S Op Journey Beyond The Supply Demand Match Organization And Ownership For The Demand Planning Process Aberdeen Strategy Research

What Are The Basic Elements Of The S Op Process Quora

S Op Software Sales And Operations Planning Qad Dynasys

S Op Demand Planning Ibp Siop Mioe Supply Chain Scm Professionals Facebook

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

Sap Ibp S Op 2 Consensus Demand Scm Connections Tutorial Youtube

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

Sales And Operations Planning A Project Manager S Guide Asana

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

Climbing The Sales Operations Maturity Ladder Stage 3 Consumer Goods Technology

1

On Demand Demand Planning And S Op Respond And Recover From Sales Demand Shocks Workday Adaptive Planning

Altemir Consulting Sales Inventory Operations Planning S Op Siop

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning Relex Solutions

1

Sales Operations Planning Omnics

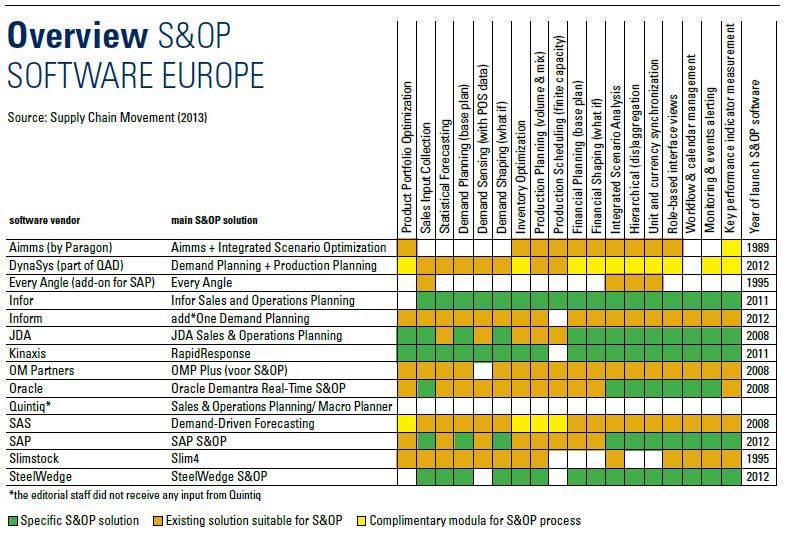

Software For Sales Operations Planning In Europe Supply Chain Movement

Ultimate Guide To Sales And Operations Planning S Op In 21

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

Sales Operations Planning Consulting Supply Velocity

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Sales Operations Planning Cirrus Supply Chain

S Op And S Oe A Symbiotic Relationship

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Integrated Business Planning Ibp S Op Evolution Agile Innovation

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Demand And Supply Management In Uncertain Times

A Paradigm Lost It S Not All About Changes In Demand

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

Sales And Operations Planning S Op Logistiikan Maailma

Sales And Operations Planning Business Forecasting Taruna Nagpal

Sales And Operations Planning Process Self Assessment

What S Holding The S Op Process Back Part Two Establishing A Business Efficiency Planning Process That Works Chainalytics

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

Sales And Operations Planning Relex Solutions

Supply Chain Graphic Of The Week The S Op Process

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Pdf Sales And Operations Planning S Op An Overview

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Sales Operations Planning Engagement Model Tvo Maine Pointe

S Op Sales And Operations Planning And Sco

Sales Operations Planning S Op And Sales Operations Execution S Oe Engineering Usa

Sales And Operations Planning

Smoother Execution Through S Op Logistics Management

Dp Vs S Op Process Flow

Achieve Excellence In Sales And Operations Planning Sapinsider

How S Op Improves Your Organization Tmc Fr

S P Process Flow Demand Planning

Sales And Operations Planning S Op 101 Smartsheet

Executive S Op Managing To Achieve Consensus Semantic Scholar

Demand Planning S Op And Inventory Controlling Model Created By Kunal Jethwa Youtube

How Does Sap Ibp Help Supply Chain Manager Align Demand Supply Plan To Annual Operating Plan Krypt Inc

Sales Role In Sales And Operation Planning Demand Planning The Sales Process Blog

Driving Supply Chain Agility With S Op And S Oe I Kinaxis

What Is Sales Operations Planning Supply Chain Minded

What Is S Op How S Op Works Demand Planning Com

S Op Myths Part 5 Lean And On Demand Manufacturing Supply Chain 24 7

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sitmi Science Industrial Technology And Management Intelligence S Op Sales And Operations Planning Process Flow Simple And Quick Explanation Of Each Steps Facebook

How Can Demand Management Drive Your Sales Operations Planning Moore

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

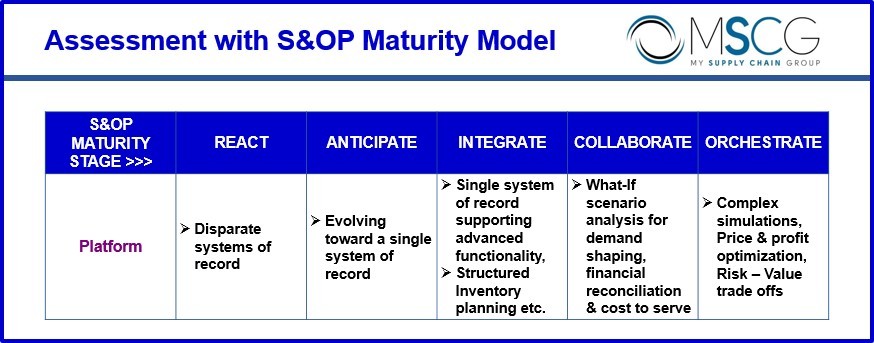

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Who Should Own Sales And Operations Planning I Kinaxis

Scielo Brasil Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa De Material De Escrita Um Estudo De Caso Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa

What Is S Op How S Op Works Demand Planning Com

S Op Maturity Going Beyond The Demand Supply Match

Sales And Operations Planning S Op

1

What Is Sales And Operations Planning S Op Plex Demandcaster

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

0 件のコメント:

コメントを投稿